Industrial Welding and

Metal Fabrication

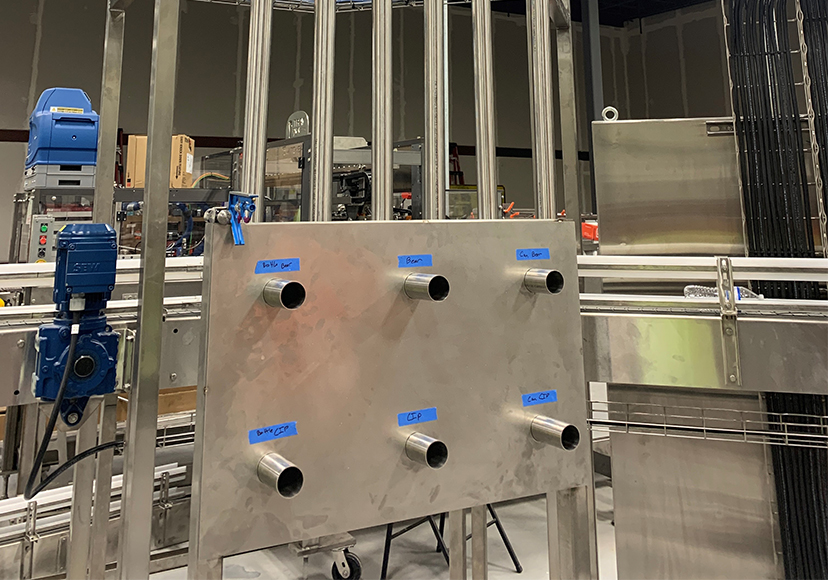

Welcome to UMI America. We offer expert industrial welding and metal fabrication services. Operating both on and off-site. Our teams of welders and metal fabricators bring precision and quality to every project. From small custom parts to large batches and complex weldments, our team utilizes top-of-the-line equipment to deliver the highest quality results to our customers.

We are conveniently based in the Lehigh Valley but are prepared to travel to accommodate customer’s needs. We are fully licensed and insured and our skilled workforce takes pride in their work. We have taken on many challenging projects in our years in business and have gained valuable knowledge of the industry that we are proud to bring to you.

best industrial welders in the industry

Certified Welders for Any Project

Our certified welding services cover a range of welding types, including:

- TIG welding

- MIG welding

- Stick welding

- Laser welding

- Orbital Welding

- Spot Welding

Whether you need aluminum welding or welding of structural steel, our licensed welders are highly skilled in their craft.

A Full Range of Metal Fabrication Services

Including:

- Sheet Metal Fabrication

- Precision Metal Fabrication

- Contract Manufacturing

- Powder Coating

- Laser Cutting

- Process and Sanitary Piping

UMI’s metal fabricators can work with different materials including:

- Titanium

- Aluminum

- Steel

- Stainless steel

A Peerless Standard of Excellence

At UMI America, we believe in adhering to the most rigorous quality control standards. This ensures clean work environments, consistent quality work, and the safety of everyone involved.

We provide quick turnaround times on parts and repairs without sacrificing quality precision.

Precision components and projects completed on time, on budget, and to the highest standard of quality and safety.