3D CAD Design

and

Laser cutting

3D CAD Designer & CNC cutting systems

Craftsmen excel with the best tools and materials available. In the world of 3D Cad Design and Laser Cutting, this could not be more true. We strive to stay on top of the latest technology. This allows our employees to push their full potential while delivering the best possible product to our customers. That is why our shop is equipped with the best 3D CAD Designer software and CNC Cutting Systems available.

Our CAD Design Services

By keeping up to date with the latest in CAD design software we can coordinate perfectly between our designers, teams, and customers. We can show 3D renderings to our customers to keep them apprised. Our welders can have accurate shop drawings to guide their cuts. Good CAD Design makes fabricating and automatic cutting efficient with optimal products. We can CAD design for a variety of materials including Steel, Stainless Steel, and Aluminum.

Our CAD design and laser cutting are augmented by the best software and hardware available. We use Autocad Fusion 360, Autodesk, Autodesk Advanced Steel, Autodesk Inventor, and Bend-Tech.

Laser Cutting

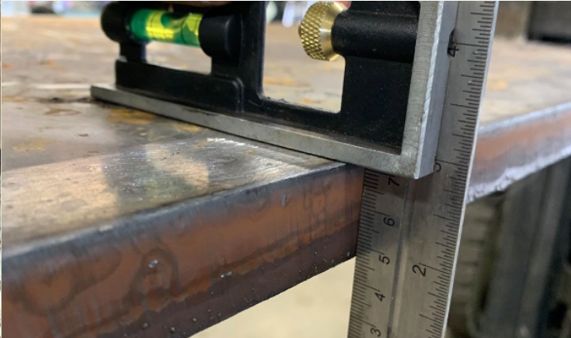

We utilize a state of the art, solid-state CNC Fiber Laser to cut all parts quickly and efficiently. We offer 8kw Flat Fiber Laser Cutting and 3kw Tube Fiber Laser Cutting. These machines can hold tolerances around the 0.002” – 0.005” mark while maintaining very high cutting speeds. The advantage of Fiber laser over Plasma is much higher tolerance and cut quality with almost no dross and straight edges even in holes. Additionally, Fiber Laser leads to higher cut speeds, lower heat input into the material, and the ability to cut non-conductive material like wood and rubber. We stock most nominal sizes in mild carbon steel, stainless, and aluminum. We are more than willing to order in anything you need and we have no minimums!

A Start-to-Finish Metalworking Company

Our vast experience, industry contacts, and comprehensive knowledge base allows us to start and carry projects through their entire production life. We can do it all from brainstorming to R&D, fabrication, processing, and installation. No job is too big or too small, too simple or too complex. We’ll do what you need exactly as you need it to be, every time. We can handle it all so that you can focus on your business.

our gallery

Color Coded Gutter Brush Assembly

Mounting Plate

Side Wing Assembly

Rendering of Platform Addition

24” Ductwork Routing Profile to See Any/All Obstacles and Cut Lengths

Rendering of Trap Door Railing and Gas Shock Placement

Spiral Cut Out

Flat laser cutting through ½” hot rolled carbon steel

Flat Laser piercing stainless

Product – 1” Thick Mild Carbon Steel Cut Quality

1” Thick Mild Carbon Steel Cut Quality

Flat Laser Cutting 10-gauge steel